MERCHANDISE

We now have shirts available for $25, and they can be shipped at additional cost if necessary. Hats, polo shirts and sweatshirts can also be ordered, please contact us if you have interest in any of these. We will need to know your size, preferred color, and the design you would like.

Please visit the STORE tab, then email us with your order.

email us: mike@customcuemaker.com

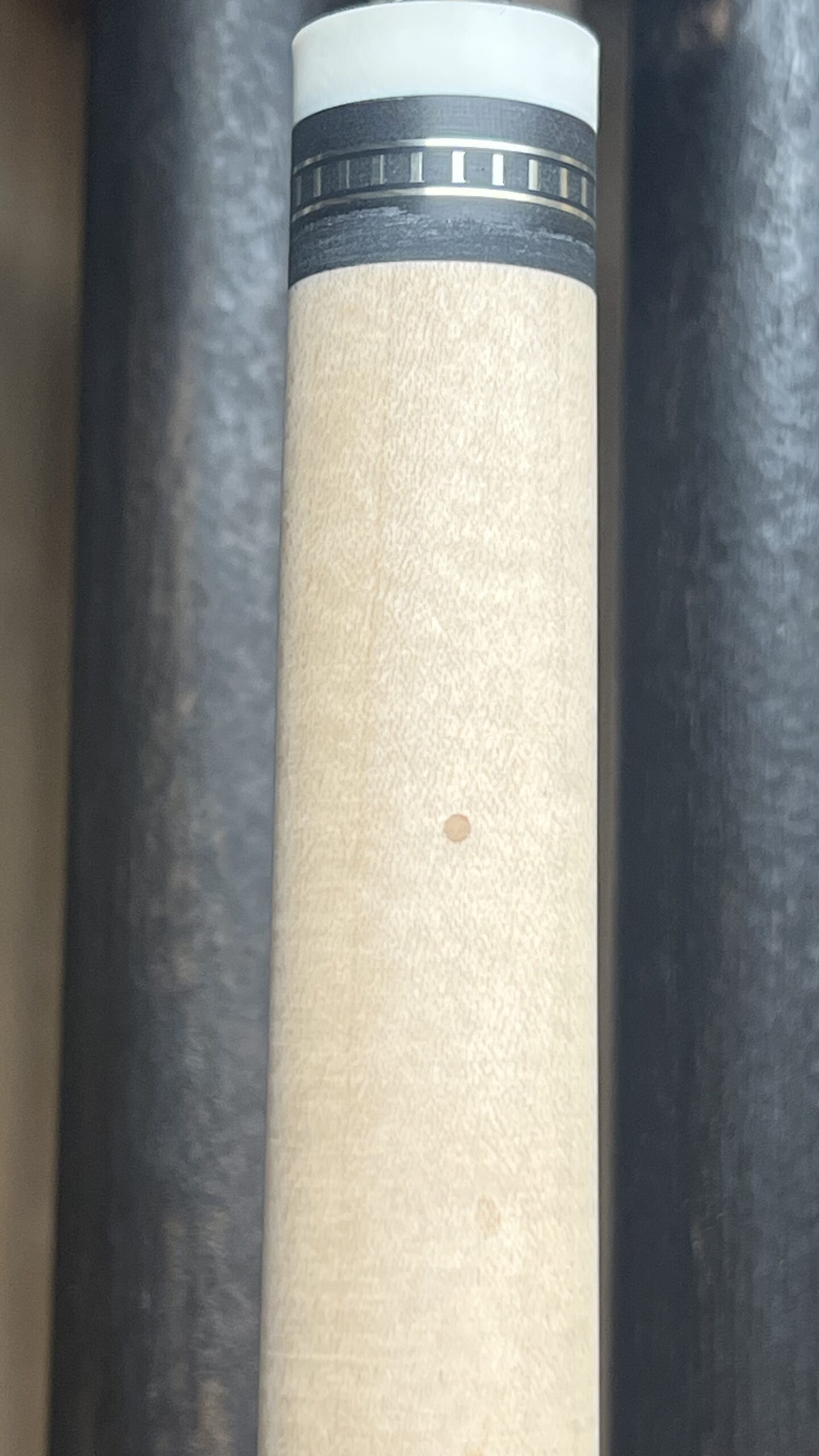

WHAT IS THE LITTLE DOT ALL ABOUT??

Many years ago when I was working at a store that sold billiards equipment, we would get returns where a cue was broken just below the joint. I’m sure that if you asked any cuemaker or cue repairman, they have seen similar catastrophic failures come in and out of their shops over the years. It’s actually shocking to me how many production cues are made with a hole that is either far too deep, or where the pin has been inserted without any glue whatsoever.

There are a variety of ways to do glue relief when inserting a pin into a pool cue. Many cuemakers, use a marine grade epoxy called West System which very strong. It is thin enough to travel up the pin if it has been made with a slot for this purpose. In fact I also use this glue for many different things such as when I am glueing up veneers, putting points into a forearm, glueing phenolic pieces to a cue, etc.

When I put a pin in the cue, or any parts with metal such as rings, I use 3M DP420. This same glue is used to attach a golf club head to the shaft… so as you can imagine, it’s quite strong. This adhesive also happens to be much thicker compared to West System glue. Too thick to effectively take advantage of the pins designed for relief with the aforementioned slot.

IN MY CUES…

To allow the excess glue to exit when the pin is being screwed in, I drill a glue “relief” hole at the base of where the pin is to be inserted. After the glue exits, I seal the hole with the end of a small toothpick to ensure the area remains filled. This ensures that the cue is very strong in this area, and more importantly…that there is SOLID material under the pin.

My personal belief is that this small and simple process is what gives our cues an incredible hit. If you have an opportunity to try one of our cues, I think you’ll find that the playability, and especially the feel and feedback are unrivaled.

The image on the left shows a catastrophic failure. As you can also see, the hole is much deeper than it needs to be, and there wasn’t a single drop of glue used when it was put in the cue. This is a typical assembly process used by many production companies, and you would be surprised at some of the big brands that do this. Only one small example of the quality differences between a production cue, and a well-built production cue but as you can see it’s a pretty important one.

Frequently Asked Questions

So what can and cannot be customized?

At the present time I have decided to stop taking custom orders. For the next few months I’m going to concentrate on completing some that are a bit over due and building some the way I want to. Possibly by the end of 2026 I will be taking orders again, more to come on this. The best way to get your hands on a Pancerny cue right now is to purchase one that is already complete, I will put details and photos up on the site when they’re ready.

Please check in the “Available Cues” section.

What if I want a low-deflection shaft?

Our cues include a low deflection shafts, whether it’s standard maple, roasted maple or “Keilwood”…or carbon fiber. And if you’re buying a cue that has a carbon fiber shaft with it, it will have matching fancy rings on the shaft.

I'm only a league player....

Whether you are an enthisiast or professional I think you will find that a Pancerny Custom will feel great in your hands!

How long are the cues?

Pancerny cues are made slightly longer, to help you get around a 9 foot table with ease. Typical length is 58.5-59 inches.